Long Term Effects for the Various Thermal Insulation Products on Investors

Good thermal insulation products not only assist in maintaining the desired temperature, but also help you to save money on the energy bills. The real challenge begins after you have decided to install thermal insulation products whether it is for a residential, commercial or industrial premise. Choosing the right thermal insulation products can initially be a daunting task as you must keep in mind the efficiency, features and the costs associated with it. Investors need to be extremely cautious as even in normal conditions, damages can take place. But, at the same time, investing in a suitable product can reduce the risk of damage occurrence and after installation threats.

Would you opt for a product that would be substantially more efficient or would you prefer a product that is cheap and inefficient? Yes, the choice is yours.

Today, investors prefer choosing an inexpensive product while ignoring the negative effects and insufficient features that come along with it. A handful of them consider the cost, based on the additional advantages or features the high-priced product comes with. Similarly, lifetime of the thermal insulation products depends on the material you install. Being able to depend on the quality and features of products installed demonstrate an important role in terms of their lifespan and stability. While deciding the materials that must be utilized, fiberglass and foam insulation generally dominate the conversation. But, making a decision and choosing between the two materials can be extremely tricky.

Long-lasting Thermal Insulation – Fiberglass vs. XLPE Foam

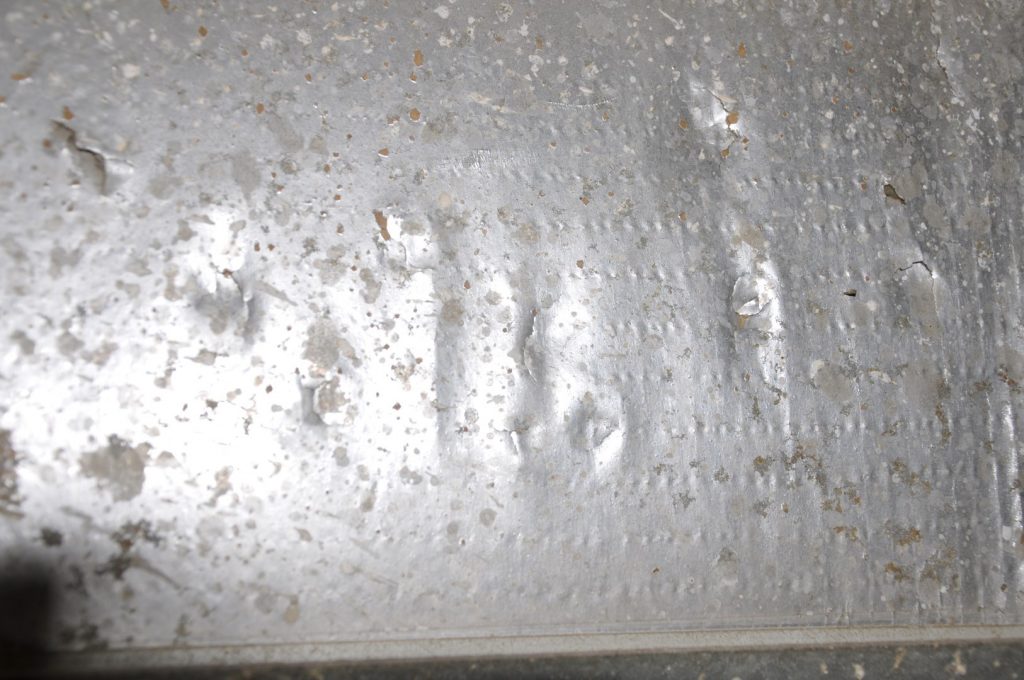

Fiberglass is bonded to an aluminum foil and gets its shape from it. But, this comes with a disadvantage as well. Due to any circumstance, if the foil gets damaged, the fibers will not be able to withstand the shape any longer. Generally, fiberglass products can be disintegrated due to the shape in itself as they do not come with dimensional stability. The skeleton of the product will fall apart if the foil gets impaired. This makes the product extremely inefficient and unreliable. It is also known to have negative health effects. Due to chemical reactions in fiberglass products, the aluminum foil gets oxidized and it is gradually destroyed. Once the foil is gone, there is no reflective effect and the lose fibers will fall apart. The integrity of the entire product becomes disputable.

On the other hand, foam products doesn’t contain lose particles/ fibers and they definitely don’t get oxidized. Since, the core of the product is foam, the damage of the foil will not affect the thermal properties and closed cell structure of the product. The foam will remain stable with or without the foil. Low thermal conductivity is the key parameter for this particular product to be installed and utilized. Reflective foil is a composite material and is protected from oxidization.

“Savings” in the beginning means high bills in the future. Industrial buildings are more exposed to tough aggressive climatic and corrosive conditions. Hence, it is crucial to invest in products that will provide stability in the prospective future. Utilization of fiberglass can jeopardize and bring your investment down to zero due to the threats of damage associated with it. The lifetime of the product depends on different applications. But, investors focus on a higher time line and the future is never too long. Investing in “cheaper” technologies of thermal insulation for the building envelope does generate double or triple cost. The expenses associated with the replacement include the cost of new product, utilization of the old product and cost of labor. It will also bring about a temporary disruption in the production until the new product is installed. It tends to be a trap as individuals are inclined to ignore the future maintenance costs. By financing a little more towards a suitable product can be useful in terms of efficiency and expenses for the future as well. It must be considered as a small investment for future savings. During projects, investors incur major costs. Their actual costs are way more than the cost of investing in a good thermal insulation solution. It is not an enormous expenditure keeping in mind the energy, product replacement and the efficiency it brings along with it.

Making the Best Choice for your Thermal Insulation Needs

Considering which product to choose for your requirements can be perplexing. But, Aerofoam has made the process uncomplicated and trouble-free for you by offering access to Aeroreflect. In particular, if you are looking for the best long-term solution, foam insulation products are not to be missed out on as you will be investing a little more initially to reduce your monthly energy bills gradually.

Contact Aerofoam for support in selecting the right thermal insulation products based on your requests. Aerofoam by Hira Industries offers a wide range of products with numerous applications. Together, we can ensure the perfect solution for your application need. To acquire more information about Aeroreflect, visit our website: www.aerofoaminsulation.com